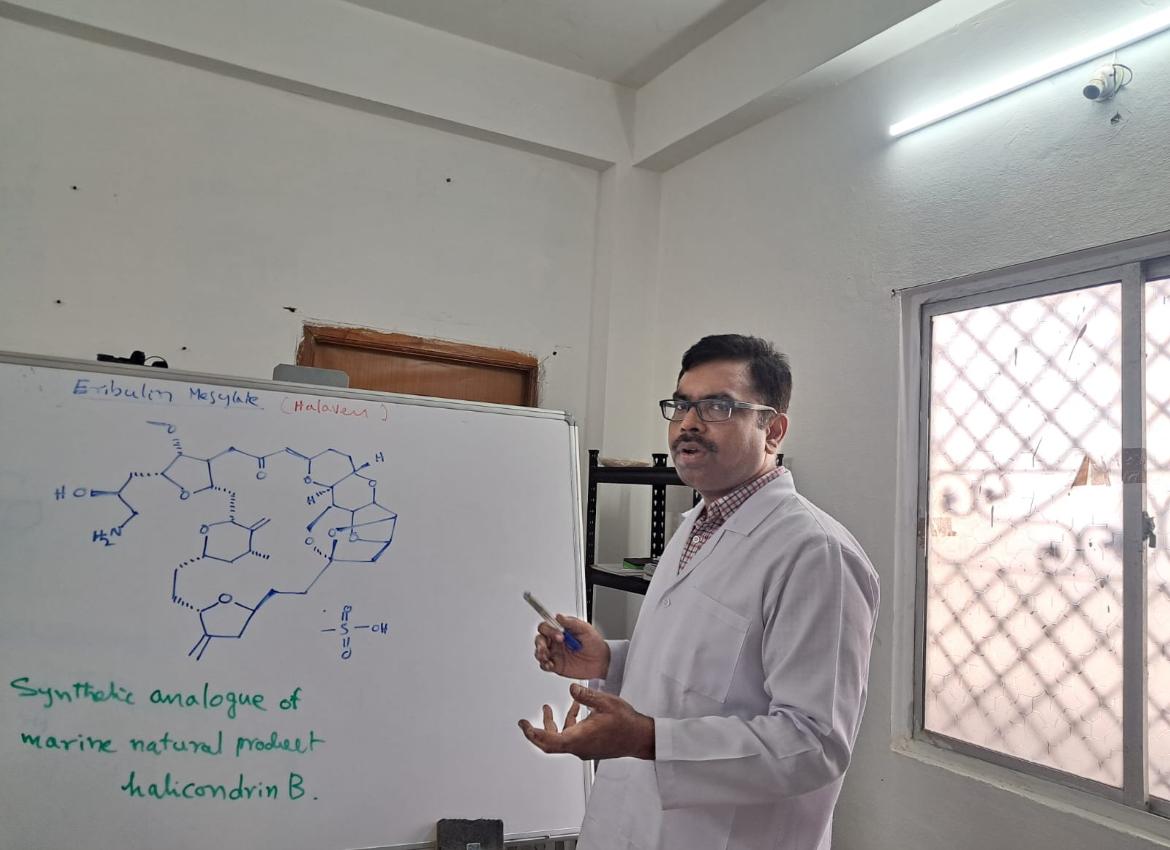

Training Programme

We offer structured education programs in pharmaceutical process development, synthetic chemistry, and quality-by-design principles, designed to bridge academic knowledge and industrial practice.

Outline of Course Content

Literature Review and Route selection

- Details Literature search,

- Design of different ROS, feasibility studies,

- ROS selection

- IP management,

- Patent infringement analysis,

- Evaluation of RMC

Process Optimization

- Design of Experiments(DOE) and Quality by Design(QbD)

- Optimization of reaction conditions,

- Reagent and Solvent selection

- Critical process parameters,

- Identification of impurities and control

- In-process and intermediate controls

Work-up and Isolation of Product

- Design simple and practical work-up procedures

- Safety considerations

- Consideration of removal of impurities and by-products.

Crystallization and Polymorphism

- Different methods of crystallization

- Chiral resolution

- Different solid forms of an API – salts, co-crystals, solvates and hydrates.

- Amorphous solids

- Characterization of solid forms

- Intellectual property and Regulatory issues

Process validation on Lab scale

- Brainstorming on practical issues for process scale-up

- Solvent recovery, reuse,

- TTD preparation

Process scale-up and Tech Transfer

- Consideration of practical issues for process scale-up

- Process safety, Equipment selection,

- Cleaning and decontamination procedures.

- Trial batches,

- Trouble-shooting

- Process modification with a change control,

- Process validation on large scale.

- Support on DMF submission and approval

Manufacturing

- Good Manufacturing Practices (GMP)

- Safety

- Continual improvement

- Stability data evaluation

- Support on DMF submission and approval

- Address DMF queries from customer/ regulatory authority

Interested please contact e-mail